Static: Don’t let it Build Up

Nothing causes equipment downtime quite like static build-up. The impact of static on machine reliability and performance can be severe. Fortunately, engineers and designers can turn to LECTRA-CON conductants from Schlegel – a full line of linear dissipator brushes that offers simple, cost-effective solutions to static electricity.

How to take the shock out.

Static electricity can be generated wherever two dissimilar materials come in contact. To complicate matters, the potential for static increases as transport speed increases. It’s easy to see why controlling static has become a bigger concern than ever.

Static dissipators are a reliable, cost-effective solution that passively (i.e. without power consumption) reduces static electricity to an acceptable level. The concept behind LECTRA-CON dissipator brushes is simple. As paper, film or other materials pass through critical points of the machine’s path, each piece is lightly brushed by the conductant. The brush draws the charge from the object, dissipating it through the machine frame to ground. In addition, dissipation is handled passively so powered ion generation type dissipators, are not needed.

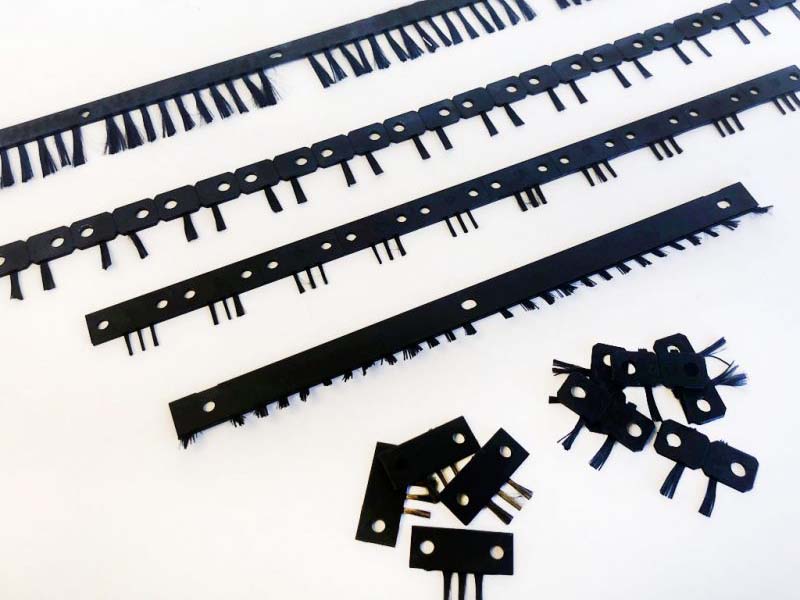

No ozone is generated with a passive dissipater like LECTRA-CON conductants. The simple design of LECTRA-CON conductants make them easier, faster and less-costly to install, minimizing machine downtime and service calls. LECTRA-CON conductants, made of conductive fibers held firmly in place by conductive plastic or metal brackets, are far more durable and effective than tinsel strips. In most applications, they’re capable of dissipating up to 96 percent of all surface static charges over the effective life of your product.

Applications include

- Copiers, printers, and faxes where they reduce the static electricity that builds up on the paper. This helps prevent paper jams, improving the reliability and productivity of the equipment.

- Automatic document feeders with rubber belts tend to charge quickly, leading to poor handling. Static dissipators enable smooth transportation of the paper.

- Packaging machines where static dissipators facilitate shrink-film handling.

Nobody has helped engineers get out of as many jams as SEM Specialty Products since pioneering static dissipation more than 35 years ago. Today, SEM SP components are used as original equipment in a variety of products, including laser printers, copiers, automatic teller machines, impact printers and faxes. They’re available in a variety of brush profiles, including small sizes that are easy to install in hard-to-access locations. What’s more, your SEM SP representative will work directly with you to provide custom design solutions for specific equipment or process requirements.

Learn how LECTRA-CON conductants can take not only the static, but the frustration, out of your paper path.