Shielded Windows

Think Schlegel EMI for Shielding – Shielded Windows

As the originator of the fabric-clad foam EMI shielding technology, Schlegel EMI is the industry’s most trusted name. We continue to set the standard for quality and innovation, designing advanced solutions for a wide range of applications. And our worldwide locations ensure that you get what you need, when you need it.

Modern electronic equipment often requires EMI Gaskets to avoid radiating EMI/RFI suspeptibility to outside sources of EMI/RFI. Maintaining electromagnetic compatibility can be an increasing challenge of the designers of today’s electronic and electrical products.

Schlegel Electronic Materials, Inc. (SEM), the preeminent manufacturer of fabric over foam EMI shielding products for the computer, telecommunications, and electronic industries, offers a full range of EMI shielding products–including gaskets, I/O backplane shielding gaskets, and highly conductive envelopes, tapes and laminates.

SEM is now proud to introduce a complete line of quality Shielded Windows. The addition to SEM’s extensive portfolio of shielding products allows SEM to be your exclusive EMI shielding supplier, to help you meet or exceed your global requirements for electromagnetic compatibilty (EMC).

Design and Consultation

SEM can offer a design and consultation service to help you to design filters for your display requirements. Displays are used in all applications from public information, through to man machine interfaces. This means that the physical properties of a filter will vary to suit its performance needs.

Consideration will often need to be given to several characteristics, including: impact resistance, solvent and abrasion resistance, reflection control, fire specifications, U.V. resistance or protection, RFI shielding, ESD, anti – static and anti – mist.

Filters can be designed to incorporate several characteristics in one part, and material selected from allyl carbonate, acrylic, polycarbonate, polyester and glass.

If a filter is designed correctly it can reduce cost, improve the readability of the display and allow your product to look at it’s best for a long time.

A display filter is the part of your equipment, which is looked at for the majority of its life. If badly designed it can have a detrimental effect on the performance of your product.

Optical Filters and Fascia Panels

SEM supplies high quality optical filters and fascia panels. These products are manufactured to suit individual customer requirements or specifications and can be made from allyl carbonate, acrylic, polycarbonate and glass. All filters can be manufactured to include screen printing and RFI shielding, (see technical information “RFI / EMC Filter windows” if necessary).

Filters can be manufactured to include many characteristics including ; contrast enhancement, reflection control, impact strength, fire specifications, abrasion and solvent resistance, polarisation and combinations of properties.

Products

RFI / EMC Filter Windows

Shielded filter windows are designed for use with electronic displays and give a high level of shielding from both internally and externally generated electromagnetic emissions. These windows can be designed to incorporate any of the filter characteristics described in the “Optical Filters and Fascia Panels” data sheet.

RFI / EMC shielded windows can be manufactured in allyl carbonate, acrylic, polycarbonate or glass. The shielding element is either a cast in micro – fine mesh (allyl carbonate only), laminated micro – fine mesh or ITO deposition.

Cast Allyl Carbonate Embedded Mesh Windows.

These shielded windows offer the superb screening performance of micro – fine mesh, combined with the outstanding characteristics of allyl carbonate (see “Optical Filters and Fascia Panels” for details on allyl carbonate).

The general properties of cast windows are:

- Micro – fine mesh is cast in to a one piece sheet, therefore no delamination problems and higher temperature specification than laminated parts.

- They can be machined to any desired profile, with or without rebates.

- Extremely good abrasion, solvent, impact and heat resistance.

- Light weight.

- Different meshes available to suit the application and mesh is blackened to reduce reflections.

- None reflective surfaces can be cast in.

- Mesh can be set at any desired angle.

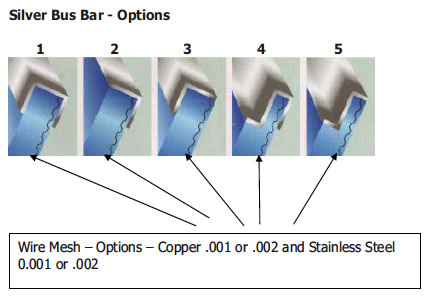

- Silver loaded bus – bar termination.

Allyl Carbonate Filter Windows

This product is cast from ADC monomer ( allyl diglycol carbonate ) and has a series of properties, which makes it ideal for the production of filter windows and fascia panels. This material is equivalent to CR39.

Properties include:

- Less than half the weight of glass

- Bright surfaces and light transmissions close to optical glass

- Refractive index close to that of crown glass

- High impact strength

- Remarkable abrasion resistance ( approximately 20 times that of acrylic )

- Resistance to pitting from hot metal sparks, 30 – 40 times higher than glass and other plastics

- Excellent resistance to acids, alkalis and to all solvents including aliphatic and aromatic hydrocarbons

- Easy surface dying

- Better scratch resistance than hard coated plastics

- Resistance to distortion by temperatures up to 130 ° C, a temperature at which acrylic resins are melted

- U.V. absorbers can be added to help protect LCD displays in strong sunlight

Allyl carbonate can be cast from 1 mm thick upwards

Typical properties of polymers cast from ADC

| Optical Properties | ASTM test method | |

|---|---|---|

| Yellowness Index | 0.73 | D 1925 |

| Haze, % | 0.21 | D 1003 |

| Refractive Index, n.20 | D 1.50 | D 542 |

| Dispersion Factor | 57 | D 542 |

| Visible Transmission, % | 93.3 | D 1003 |

| Ultraviolet Transmission, % | ||

| ( 3 mm thickness) | ||

| at 300 nm. | 25 | |

| at 340 nm. | 77 | |

| at 380 nm. | 88 |

| Physical and mechanical properties | ASTM test method | |

|---|---|---|

| Density, g/cc | 1.311 | D 792 |

| Tensile Modulus, (Mpa) | 2.4 | D 638 |

| Taber Abrasion, ( x P.M.M.A.) | 20 | D 1044 |

| (modified) | ||

| Rockwell Hardness, (M) | 97 | D 785 |

| IZOD Impact Resistance KJ/mq. | 7.85 | D 256 |

| (Unnotched at 23 C) | (modified) |

| Chemical resistance | ASTM test method | |

|---|---|---|

| 7 days immersion at 23 C | ||

| Water : | ||

| absorption, % | 0.4 | |

| haze variation, % | 0.07 | |

| Acetone : | ||

| absorption, % | 0.78 | |

| haze variation, % | 0 | |

| Toluene : | ||

| absorption, % | 0.4 | |

| haze variation, % | 0 | |

| Ethyl Alcohol 95% : | ||

| absorption, % | 0.1 | |

| haze variation, % | 0.05 | |

| Trichloroethylene : | ||

| absorption, % | 0.04 | |

| haze variation, % | 0.06 | |

| H.D.T. 1,82 Mpa, C | 69 | D 64 |

| Thermal expansion | |

|---|---|

| Linear coeff./ C | |

| from -40 to 25 C | 0.81 x 10-4 |

| from 25 to 75 C | 1.20 x 10-4 |

| from 75 to 125 C | 1.43 x 10-4 |

Laminated Mesh Windows

(see “Optical Filters and Fascia Panels” for details of the filter range).

The general properties of laminated windows are:

- Micro – fine mesh is laminated in between your selected filter medium.

- Plastic versions can be machined to any desired profile, and glass versions can be constructed with or without rebates.

- Different meshes available to suit the application and mesh is blackened to reduce reflections.

- None reflective surfaces can be included.

- Mesh can be set at any desired angle.

- Various termination methods are available including; tape edge, mesh over gasket, flying mesh, silver bus – bar.

Shielded Windows

ITO Deposition Windows

Indium Tin Oxide ( ITO ), is a transparent semiconductor which can be coated onto optical filter materials. ITO benefits over metal depositions because it is more transparent and less reflective, for a given impedance level. A good ITO coating will have optical transmission levels of greater than 75 %.

The ITO coating can be sputtered onto glass or plastic and has good chemical and mechanical durability. It will also not oxidize when exposed to air.

The oxygen content of the coating is adjusted to a compromise point, giving good optical transparency and low impedance, normally between 10 – 40 Ohms / square for shielding.

The shielding effect of thin film coatings is due to reflection of the electromagnetic wave. This means that the coatings are only effective when the wave impedance is greater than the coating impedance. This in turn means that the coatings have no effect in the magnetic, or H – Field, and are not suitable for all applications. There can also be some optical limitations to ITO coated windows and these should be fully discussed before selection is made.

Performance of an ITO window will depend on its impedance and the field impedance, but generally will produce between 80 and 120 dB attenuation in the E – Field, and around 20 dB for Plane waves.

Polycarbonate Filters

Polycarbonate is usually used when impact strength or fire retardance is required. These filters are made from proprietary sheet material and normally coated with a hard coat to give abrasion and solvent resistance.

There are only a few standard tints available for polycarbonate, but others can be produced when necessary, in relatively small volumes. We have several techniques available to enable the production of polycarbonate contrast enhancement filters.

Properties of the polycarbonate will depend on the selected grade.

Glass Filters.

Glass filters can be produced plane, matt etched or with multilayer AR coating. These filters can also be toughened when required. Laminations can be built to include all fi ltering characteristics already mentioned.

Available Coatings For Acrylic and Polycarbonate

A range of optical coatings are available for the surfaces of acrylic and polycarbonate filters. Coatings can offer a selection of the following characteristics ;

- Abrasion resistance

- Solvent resistance

- Anti – glare ( matt coating )

- Anti – mist

- Anti – Newton ring

- Multi – layer anti – refl ective ( limited to a small range of product )

Acrylic Filters

The large range of tints available allows specific wavelengths to be transmitted. This can be used to contrast enhance, color correct or produce band pass filters. Infra-red filters are also manufactured to block visible light and transmit IR at around 90%.

All acrylic filters can be finished with a hard coat, for abrasion and solvent resistance, which can be applied as a gloss or matt surface.

| Optical Properties | |

| Refractive Index nD20 | 1.492 |

| Light Transmission % | 92 |

| Physical and mechanical properties | |

| Density, g/cc | 1.18 |

| Tensile Strength N/mm2 | 75 |

| Elongation at Break % | 4.5 |

| Bending Strength N/mm2 | 135 |

| Notched Impact Strength | 2 |

| Modulus of Elasticity N/mm2 | 3300 |

| Thermal Characteristics | |

| Linear coeff./ C 0 - 50 ° C | 70 x 10-6 |

| Vicat softening point ° C | 100 |

| Temp for continuous use ° C | 70 |