Elastomers

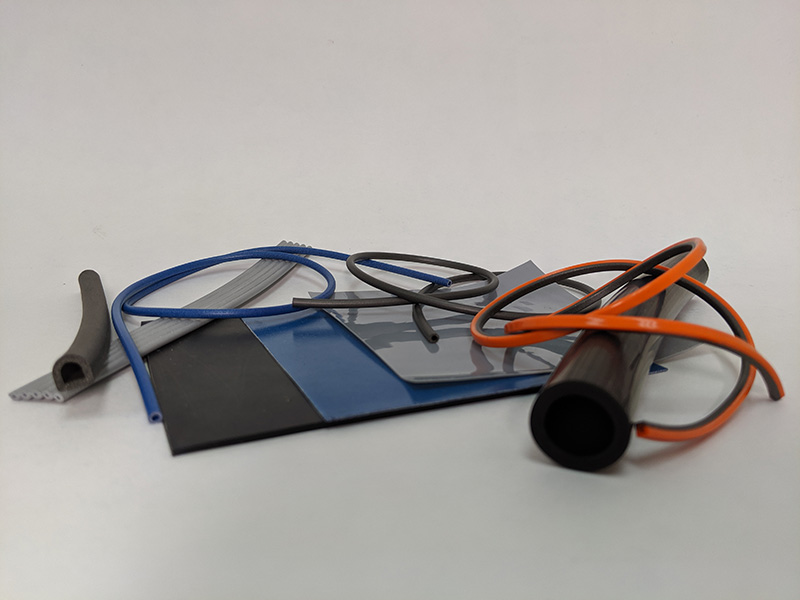

Schlegel Electronic Materials, Inc. (SEM) line of silicone gaskets provides shielding capability in diverse markets and applications, including the military, aerospace, medical, fluid seal, environmental and microwave applications. Our silicone elastomers are specifically designed for gasketing applications that require high levels of attenuation up to 120 db.

SEM is renowned for its high quality EMI shielding gaskets. We provide a full family of products to meet a wide spectrum of shielding needs. Our silicone gaskets meet customer needs in a variety of markets, with very competitive pricing. Engineers can now fulfill all their shielding needs from one manufacturer, rather than having to go through multiple distributors or resellers.

Silicone, the base material for elastomers, has environmental sealing properties. Shielding is achieved by incorporating various media in the silicone, depending on the product. Wire is used to provide conductivity in the oriented silicone line and a non-corrosive particle is added to the extruded parts. Because conductive elastomers can be extruded, many different profiles and lengths can be made to suit any application.

Doubleshield Surface Mount Gasket Grounding Pads

Ensure electrical performance without breaking under mechanical or environmental stress. The flexible and easily compressible grounding pad can take up tolerances and close the gap between a PCB and another component, in addition to providing a reliable grounding contact.

Find product description, dimensions, properties, and applications here.

Gaskets

Wire Oriented in Silicone Gaskets (WOS)

Avoid the risk of EMI or environmental seal failure.

The E/Gasket-WOS, Wire Oriented in Silicone, stands up to the test. Schlegel Electronic Materials’ (SEM) E/Gasket-WOS combines the benefits of two robust materials into one gasket. Its high- quality commercial or military grade silicone maintains a strong environmental seal, while a choice of wire substrates offers both high levels of attenuation and galvanic compatibility/ E/Gasket-WOS also resists compression set over a wide temperature range for lasting performance.

Available in both solid and sponge silicone, with aluminum or monel embedded wires. E/Gasket-WOS comes in sheet and strip forms-with or without silicone compatible Pressure Sensitive Adhesive (PSA).

Custom orders are available upon request.

For performance characteristics and ordering information please download SEM ’s Conductive Elastomers pdf or contact your SEM representative.

Specifications

| Metal | Specification | Elastomer | Specification |

|---|---|---|---|

| Monel Wore | QN-N-281, 0.0045 dia | Solid Silicone (A) | ZZ-R-765-2b 40 |

| Aluminium Wire | Alloy 5056, 0.005 dia | Sponge Silicone | AMS 3195 |

| SnPhBronze Wire | ASTM B1505, 0.0045 dia | Flourosilicone | Mil-R-25988 Gr |

| Tin Plated Copper | QQW-343 | Silicone (B) | WSI-9206 TYPE1 |

Most commonly used substrates. Other combinations are available upon request.

| Silicone/ Monel Wire | Sponge Silicon/ Monel Wire | Solid Silicone/ Aluminium | Sponge Silicone/ Aluminium | Solid Silicone/ Tin Plated Copper Wiire | |

|---|---|---|---|---|---|

| Shielding db: | |||||

| 200 Khz | 70 | 70 | 70 | 70 | 80 |

| 100 Mhz | 120 | 120 | 120 | 120 | 120 |

| 1. Ghz | 100 | 100 | 100 | 100 | 105 |

| Closing Force (psi) | 25 - 100 | 25 - 100 | 15 - 75 | 15 - 75 | 25 - 100 |

| Compression Set (@50 psi) | 2% | 5% | 2% | 5% | 8% |

| Temperature range (ºC) | -0.325 | -0.325 | -0.325 | -0.325 | -0.325 |

| EMP Survivability | yes | yes | yes | yes | yes |

| Color | grey | grey | blue | grey | blue |

| Wire count (sq. in.) | 900 | 900 | 900 | 900 | 900 |

Conductive Silicone Elastomer Gaskets (CSE)

An application requiring reliable, cost-effective EMI shielding needs Schlegel Electronics Materials’ (SEM) Conductive Silicone Elastomer Gaskets-E/Gasket-CSE. SEM’s E/Gasket-CSE offers a durable composite of high-quality silicone and conductive microscopic particles–manufactured to strict formulations—that provide shielding to answer any EMI challenge. Three popular composites are: silver-plated aluminum filled elastomers which are specially formulated for applications requiring both high levels of shielding and galvanic compatibility to a wide variety of metal interfaces. Silver-plated copper filled elastomers provide a higher level of shielding than most particle-filled elastomers. The nickel-coated graphite elastomers are available for applications requiring less conductivity but better galvanic compatibility to mating surfaces in applications with environmental exposure. Custom compounds can be formulated to fit specific requirements

E/Gasket-CSE is available in molded, sheet or extruded form from D-shapes to O-rings.

For performance characteristics and ordering information please download SEM’s Conductive Elastomers Catalog or contact your SEM representative.

| Conductive Particles | Carbon | Nickel Graphite | Silver Glass | Silver Nickel | Silver Aluminium | Silver Copper | Silver Low Density |

|---|---|---|---|---|---|---|---|

| MIL-G-83528 Type | N/A | N/A | M | L | B, D | A, C, K | J |

| Operating Temperature | |||||||

| Min (ºC) | -55 | -55 | -55 | -55 | -55 | -55 | -55 |

| Max (ºC) | 175 | 200 | 200 | 180 | 200 | 125 | 160 |

| Specific Gravity | 1.2 | 1.95 | 1.8 | 4 | 2 | 3.5 | 1.7 |

| Hardness (Shore A) Durometer | 70 | 70 | 65 | 75 | 65 | 65/75/85 | 45 |

| Compression Deflection (% min) | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 8 |

| Tensile Strength (lbs/sq-in) | 450 | 150 | 200 | 200 | 200 | 200 | 150 |

| Elongation (%) | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 8 |

| Volume Resistivity (ohm-cm) | 8 | 0.1 | 0.005 | 0.005 | 0.008 | 0.004 | 0.001 |

| Shielding Effectiveness (20mhz-10ghz) | 40 | 80 | 110 | 100 | 110 | 110 | 80 |

| EMP survivability | yes | yes | yes | yes | yes | yes | yes |

Die-Cut Composite Gaskets

Typical applications include connectors, avionics equipment, engine management systems and wave guides.

These gasket materials are an oriented matrix of wires bonded into a solid or sponge elastomer base. This material allows good electrical contact on less than ideal surface finishes while not allowing electrical conduction across the width of the gasket.

A flourosilicone variant is available for applications where fuel and oil resistance is necessary:

Woven aluminum mesh impregnated with a silicone or neoprene elastomer.

Expanded Monel mesh filled with a silicone elastomer.