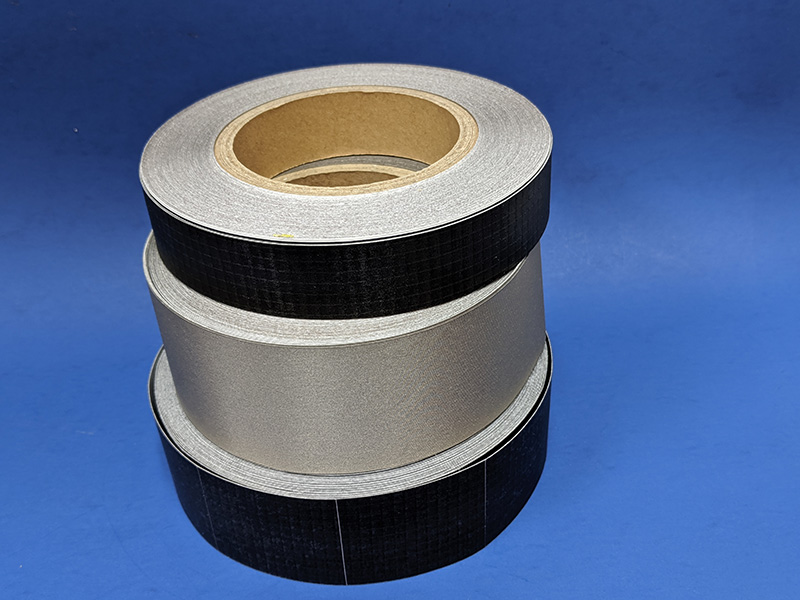

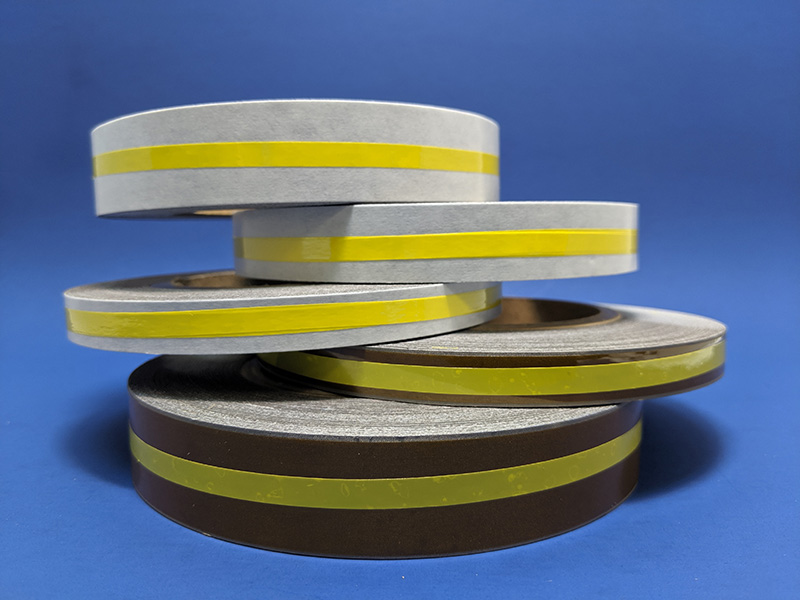

Conductive Tapes

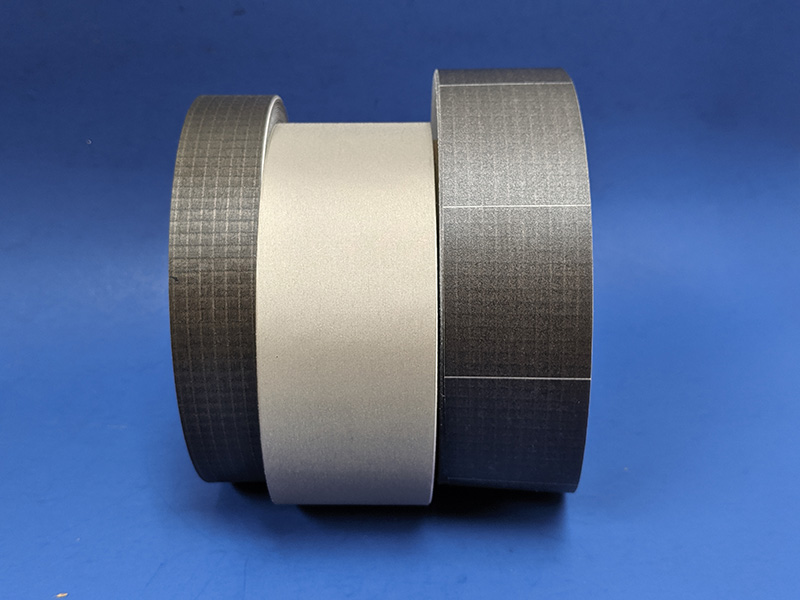

Schlegel Electronic Materials, Inc. (SEM) expanded line of Conductive Tapes meets the customer needs for flexibility, higher conductivity, and easier installation. They are available with conductive and non-conductive adhesives and in a wide range of widths.

Typical applications include cable Shielding terminations and joining metal panels together at the seams of an enclosure. Foil tapes are a cost-effective shielding solution for a wide range of uses. They can be particularly useful during the development and test phases of projects to be used as “fixes” for EMI problems.

SEM’s masked conductive tapes are also available and can be used as a gasket substrate on painted or stove enameled enclosures.

Also available are special purpose adhesive tapes to include:

- Pressure sensitive adhesive die-cuts

- High-tack adhesive die-cuts

- Low residueadhesive die-cuts

- Silicone adhesive die-cuts

- Insulation adhesive die-cuts

- Heat resistive adhesive die-cuts

SEM’s Conductive Tapes feature superior shear strength, 7.6 kPa (72+ hours @ 1.1 psi) in accordance to (PSTC #7) ASTM D 3654, and peel strength, 10.2 N/2.5 cm. (36.07 oz/inch width) in accordance to PSTC #1) ASTM D 3330, when compared to other EMI shielding tapes. This is made possible by a unique, cross-linking acrylic based, conductive Pressure Sensitive Adhesive (PSA) that also allows the tapes to be designed into higher temperature applications. The PSA is fire-rated to UL 510, and excessive pressure is not required for application to the end unit. There is now an easy-to-apply tape to fit most every EMI shielding design need.