In engineering, finding solutions that perfectly balance functionality, versatility, and efficiency is a constant pursuit. When it comes to EMI shielding and electrical conductivity, engineers often face the challenge of selecting materials that offer optimal performance across a range of requirements.

SEM’s Conductive Foam Features:

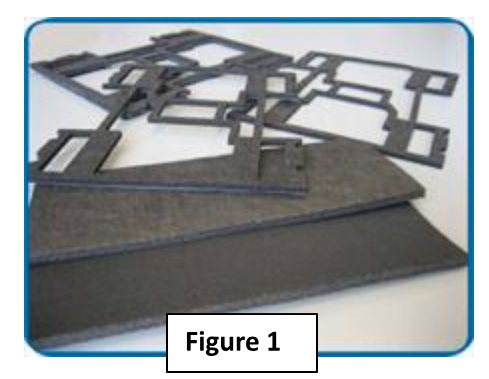

SEM offers a line of EMI foam, CF Conductive Foam, a highly resilient Nickel-Copper polyurethane foam sandwiched between our knitted and non-woven fabrics to form die-cut gaskets (Fig. 1).

Schlegel Electronic Materials (SEM) provides a conductive foam that delivers conformity, cavity-to-cavity EMI shielding, conductivity at low compression forces, and exceptional effectiveness at very high frequencies. Here we explore the features, benefits, and applications of SEM’s conductive foam, unraveling its immense potential for engineers across diverse industries.

Key features include:

1. Conformity

2. Cavity-to-Cavity EMI Shielding

3. Conductivity at Low Compression Forces

4. Effectiveness at Very High Frequencies

Benefits of SEM’s Conductive Foam:

1. Enhanced Design Flexibility

2. Improved Performance and Reliability

3. Simplified Assembly and Installation

Applications of Conductive Foam:

1. Electronics and Telecommunications

2. Medical Devices

3. Aerospace and Defense

SEM’s conductive foam emerges as a game-changer for engineers seeking effective EMI shielding and electrical conductivity solutions.

Visit https://www.schlegelemi.com/conductive-foam/ to learn more and unlock the full potential of your engineering projects.