In the ever-evolving field of electronics, engineers constantly strive to improve the performance and reliability of electronic devices. They face a critical challenge in managing thermal and electromagnetic interference (EMI) issues.

Fortunately, a solution addresses both problems simultaneously: combination thermal/EMI absorber products.

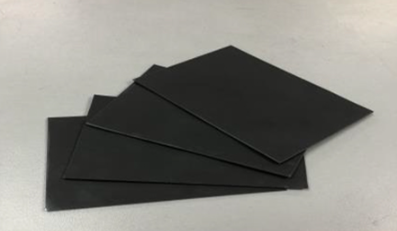

The TIMSorb® series is the latest hybrid thermal/absorber management material. These innovative materials serve as thermal interfaces between heat sources and heat transfer devices or metal chassis while mitigating unwanted energy coupling, resonances, and surface currents causing board-level EMI issues. Here, we will explore the features, benefits, and contemporary application examples of these cutting-edge products.

Features and Benefits

Combination thermal/EMI absorber products offer several key features and benefits that make them an ideal choice for engineers dealing with thermal and EMI challenges:

Efficient Thermal Management

These products possess excellent thermal conductivity, ensuring efficient heat transfer between heat sources, such as integrated circuits (ICs), and heat sinks, or other heat transfer devices. By reducing thermal resistance, they help prevent overheating and enhance the overall performance and lifespan of electronic components.

EMI Suppression

The combination of thermal and EMI absorber properties allows these materials to attenuate unwanted electromagnetic energy, minimizing interference and potential disruptions to nearby electronic devices. They work by absorbing and dissipating electromagnetic waves, reducing the risk of EMI-related issues.

Enhanced Reliability

Combining thermal/EMI absorber products contributes to electronic device reliability by effectively managing thermal and EMI concerns. They help prevent temperature-related failures and ensure electromagnetic compatibility, enabling smoother operation even in complex and noise-sensitive applications.

About TIMSorb®

The dual-functional TimSorb line features:

- OP-7400, a hybrid absorber/thermal

management material used for

premium EMI mitigation. - OP-7500, a premium grade thermal

conductivity vs. OP-7400 with

excellent EMI mitigation. - OP- 7600, the best of both worlds

having premium EMI attenuation

performance and excellent thermal

conductivity. - OP-7400/7500/7600 grades are used

like traditional thermal interface

materials between a heat source

such as an integrated circuit and

heat sink or other heat transfer

devices such as a metal chassis.

Contemporary Application Examples

Let’s explore some real-world application examples where engineers can benefit from using combination thermal/EMI absorber products:

High-Speed Data Communication

In applications involving high-speed data transmissions, such as servers, routers, and networking equipment, thermal management is crucial for maintaining optimal performance.

Combination thermal/EMI absorber products can be applied as thermal interface materials between ICs and heat sinks, preventing thermal throttling and ensuring efficient heat dissipation.

Simultaneously, they suppress EMI emissions that may interfere with the sensitive electronic circuitry, minimizing data corruption and improving overall system reliability.

Automotive Electronics

The automotive industry is rapidly adopting advanced electronic systems, including infotainment units, driver assistance systems, and powertrain controls. These systems generate substantial heat and can be susceptible to EMI interference.

By utilizing combination thermal/EMI absorber products, engineers can address both thermal management and EMI issues effectively. These materials can be employed as thermal interface materials between critical components and metal chassis, ensuring efficient heat transfer while suppressing EMI emissions that may interfere with other vehicle electronics or external communication systems.

Consumer Electronics

In compact and densely populated consumer electronic devices like smartphones, tablets, and

wearables, managing both thermal and EMI challenges is crucial. Combination thermal/EMI absorber products can be integrated into the design to improve thermal dissipation between heat-generating components and the device’s chassis.

Furthermore, they help mitigate EMI emissions, reducing the risk of interference with sensitive antennas or other electronic components, resulting in better device performance and user experience.

Combination thermal/EMI absorber products, like TIMSorb, offer a compelling solution to engineers who must address thermal and EMI challenges in electronics simultaneously. With their efficient thermal management capabilities and EMI suppression properties, TIMSorb hybrid EMI/Thermal materials enhance the reliability and performance of electronic devices. In contemporary applications across various industries, they play a vital role in ensuring optimal thermal dissipation, reducing the risk of EMI-related issues, and improving overall system integrity. Learn more or get free samples here.

As technology continues to advance, engineers can rely on Schlegel Electronic Materials to bring innovative solutions to the marketplace.