Description

Features and Benefits:

• Superior thermal performance

• 2.0 W/m-K thermal conductivity

• Good EMI suppression

• Easy to dispense

• Easy storage

• Ultra-conforming for fragile and

low stress applications

• Ambient or accelerated cure schedules in elevated temperature

Typical Applications

• Automotive electronics

• PCBA to housing

• Discrete components to housing

• Fiber optic telecommunications

equipment

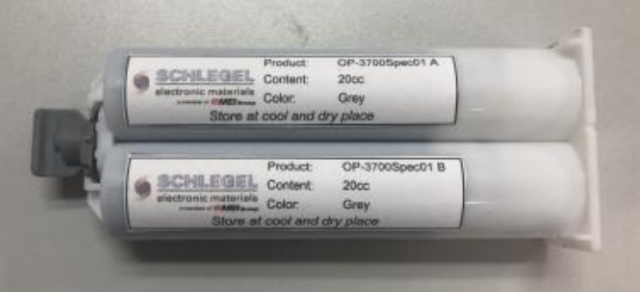

Appliances supplied:

• Dispensing Gun

• Static mixer

Direction for Use:

• Install the twin barrel onto the

gun, attach static mixer in front

end.

• Squeeze the handle to press

puncher for materials to come