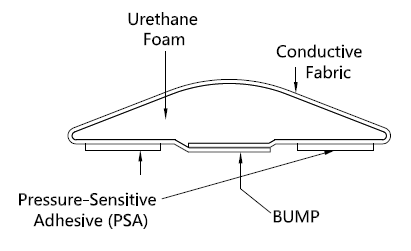

Schlegel Electronic Materials, Inc. (SEM) introduces DynaShear and DynaGreenTM an innovative EMI shielding gasket family for the shielding of modules in card/cages environment that is able to offer superior features over metal fingerstocks and current Fabric-Over-Foam gaskets . DynaShear and DynaGreenTM utilize the bump technology that result from a three axis development program :

– SEM famous special flat D-Profiles with bump.

– Low memory ultra soft foam type 7.

– Abrasion resistant conductive fabrics.

Both programs DynaShear and DynaGreenTM are supplied with a flammability UL94-V0 rating but DynaGreenTM utilizes a special SEM ‘s formulation for the retardants making that series Halogen Free according to IEC 61249-2-21 ( 900 ppm max. bromine , 900 ppm max chlorine max. with a total of max. 1500 ppm ).

| Height Width | 1.5mm | 2.0mm | 2.3mm | 2.7mm | 3.0mm | 3.3mm | 3.5mm | 3.8mm |

|---|---|---|---|---|---|---|---|---|

| 6mm | EY37n2Z xxxxÿ(HF) | EK97n2Z xxxx(HF) | EQ67n2Z xxxx(HF) | EQ77n2Z xxxx(HF) | E2S7n2Z xxxx(HF) | EQ87n2Z xxxx(HF) | E2W7n2Z xxxx(HF) | EQ97n2Z xxxx(HF) |

| 8mm | EY47n2Z xxxx(HF) | EV37n2Z xxxx(HF) | EP17n2Z xxxx(HF) | EU87n2Z xxxx(HF) | E2T7n2Z xxxx(HF) | EV67n2Z xxxx(HF) | E2X7n2Z xxxx(HF) | EV77n2Z xxxx(HF) |

| 10mm | EY57n2Z xxxx(HF) | EJ87n2Z xxxx(HF) | EJ97n2Z xxxx(HF) | EK17n2Z xxxx(HF) | E2P7n2Z xxxx(HF) | EK27n2Z xxxx(HF) | E2R7n2Z xxxx(HF) | EK37n2Z xxxx(HF) |

| 12.7mm | EY27n2Z xxxx(HF) | EK47n2Z xxxx(HF) | EK57n2Z xxxx(HF) | EK67n2Z xxxx(HF) | E2U7n2Z xxxx(HF) | EK77n2Z xxxx(HF) | E2Y7n2Z xxxx(HF) | EK87n2Z xxxx(HF) |

| 17mm | EY67n2Z xxxx(HF) | EY77n2Z xxxx(HF) | EV87n2Z xxxx(HF) | EY87n2Z xxxx(HF) | E2V7n2Z xxxx(HF) | EY97n2Z xxxx(HF) | E3B7n2Z xxxx(HF) | E1A7n2Z xxxx(HF) |

n : specifies the fabric type (3: NiCu-C70 and 4 :NiCu-C12); xxxx : specifies the length in the form of xx.xx”;

HF : DYNAGREEN TM ;

Standard parts supplied with wide release liner and 2 strips of adhesive.

Height given for untapped and uncompressed parts.

DynaShear / DynaGreenTM : Technical Features

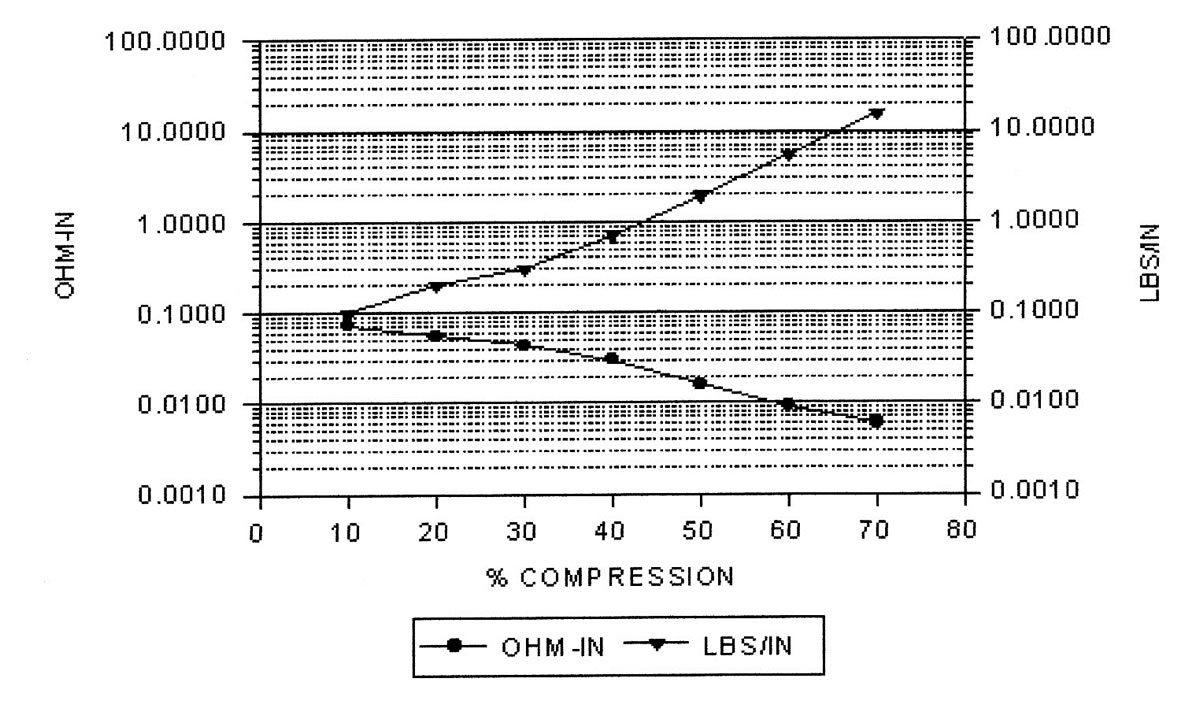

Compression force : 0.70 lbs.-inch at 40 % compression (*)

Contact resistance : 0.012 Ohms-inch at 40 % compression (*)

Compression set : 15.4 % when compressed 50 % for 22 hrs. at 70°C (*)

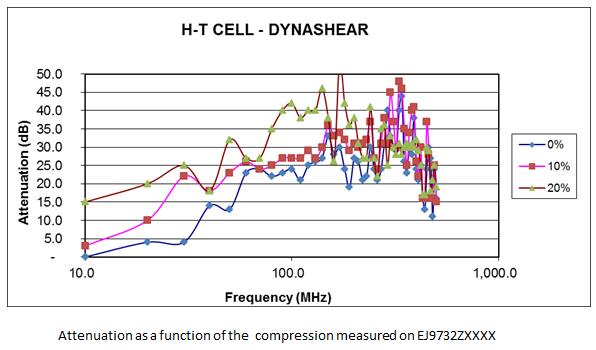

Recommended compression for max. shielding : See table in the “gasket selection “section .

Abrasion resistance : No change in surface resistivity 800,000 cycles (NiCu-C70)

General Service Temperature: -40°C (-40°F) , 70°C (158°F)

Flammability: UL94-V0 certified (under the component program of Underwriters Laboratories Inc. in specified claddings and thicknesses)

Shielding Effectiveness: 96 dB (average) 20 MHz-10 GHz – Mil DTL 83528 C (NiCu-C70)

3M Adhesive 90° peel strength on stainless steel : 128/142 Oz./in after 72 hours –ASTM D3330

(*) : measured on EJ9732ZXXXX

DynaShear / DynaGreenTM : Gasket selection

These series of D-shape gaskets are characterized by the presence of a bump at the bottom surface so to preserve a substantial shielding effectiveness even when compression is low. RF measurement shows that below 20 % and down to almost 0% compression, Shielding Effectiveness is about the value measured at 20 % compression .The thickness of the bump is typically 0.3 mm . The specific adhesive used on this series has been selected for its high shear strength and has a nominal thickness of 0.17 mm .

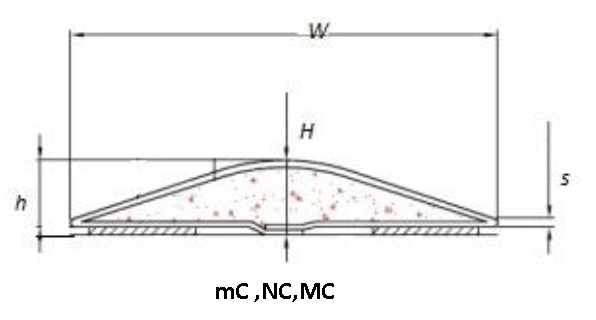

The dimensions provided in this catalog are the dimensions for the parts un-taped and in an uncompressed state . When the part is taped, the bump is slightly compressed. Therefore, the following values and table are provided to help the selection of the right profile versus the nominal gap between modules. The compression values for the gasket (% from free height) are given in black and the corresponding values of the gap between modules are provided in blue (in mm) .

Minimum Compression (mC):

mC = 1 %

Maximum Gap (MG) :

MG (mm) = 0.99 *h with h (mm) =[ ( H – 0.3 ) + 0.17 ] .

Nominal Compression (NC) : SEM recommend to compress 50 % of the free height h

NC (%) =50

Nominal Gap (NG) :

NG (mm) = h * 0.5

Max. Compression (MC):

MC (%) = (h-S)/h* 100 with S(mm)= s + 0.17

Minimum Gap (mG) :

mG = S

| P/N | H(mm) | W(mm) | s(mm) | h(mm) | mC(%) | MG(mm) | NC(%) | NG(mm) | MC(%) | mG(mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| EY3 | 1.5 | 6 | 0.36 | 1.37 | 1 | 1.36 | 50 | 0.69 | 61.31 | 0.53 |

| EY4 | 1.5 | 8 | 0.39 | 1.37 | 1 | 1.36 | 50 | 0.69 | 59.12 | 0.56 |

| EY5 | 1.5 | 10 | 0.39 | 1.37 | 1 | 1.36 | 50 | 0.69 | 59.12 | 0.56 |

| EY2 | 1.5 | 12.7 | 0.4 | 1.37 | 1 | 1.36 | 50 | 0.69 | 58.39 | 0.57 |

| EY6 | 1.5 | 17 | 0.41 | 1.37 | 1 | 1.36 | 50 | 0.69 | 57.66 | 0.58 |

| EK9 | 2 | 6 | 0.35 | 1.87 | 1 | 1.85 | 50 | 0.94 | 72.19 | 0.52 |

| EV3 | 2 | 8 | 0.42 | 1.87 | 1 | 1.85 | 50 | 0.94 | 68.45 | 0.59 |

| EJ8 | 2 | 10 | 0.48 | 1.87 | 1 | 1.85 | 50 | 0.94 | 62.54 | 0.65 |

| EK4 | 2 | 12.7 | 0.39 | 1.87 | 1 | 1.85 | 50 | 0.94 | 70.05 | 0.56 |

| EY7 | 2 | 17 | 0.54 | 1.87 | 1 | 1.85 | 50 | 0.94 | 62.03 | 0.71 |

| EQ6 | 2.3 | 6 | 0.36 | 2.17 | 1 | 2.15 | 50 | 1.09 | 75.58 | 0.53 |

| EP1 | 2.3 | 8 | 0.39 | 2.17 | 1 | 2.15 | 50 | 1.09 | 74.19 | 0.56 |

| EJ9 | 2.3 | 10 | 0.39 | 2.17 | 1 | 2.15 | 50 | 1.09 | 74.19 | 0.56 |

| EK5 | 2.3 | 12.7 | 0.6 | 2.17 | 1 | 2.15 | 50 | 1.09 | 64.52 | 0.77 |

| EV8 | 2.3 | 17 | 0.75 | 2.17 | 1 | 2.15 | 50 | 1.09 | 57.6 | 0.92 |

| EQ7 | 2.7 | 6 | 0.36 | 2.57 | 1 | 2.54 | 50 | 1.29 | 79.38 | 0.53 |

| EU8 | 2.7 | 8 | 0.37 | 2.57 | 1 | 2.54 | 50 | 1.29 | 78.99 | 0.54 |

| EK1 | 2.7 | 10 | 0.39 | 2.57 | 1 | 2.54 | 50 | 1.29 | 78.21 | 0.56 |

| EK6 | 2.7 | 12.7 | 0.57 | 2.57 | 1 | 2.54 | 50 | 1.29 | 71.21 | 0.74 |

| EY8 | 2.7 | 17 | 0.8 | 2.57 | 1 | 2.54 | 50 | 1.29 | 62.26 | 0.97 |

| E2S | 3 | 6 | 0.34 | 2.87 | 1 | 2.84 | 50 | 1.44 | 82.23 | 0.51 |

| E2T | 3 | 8 | 0.37 | 2.87 | 1 | 2.84 | 50 | 1.44 | 81.18 | 0.54 |

| E2P | 3 | 10 | 0.54 | 2.87 | 1 | 2.84 | 50 | 1.44 | 75.26 | 0.71 |

| E2U | 3 | 12.7 | 0.58 | 2.87 | 1 | 2.84 | 50 | 1.44 | 73.87 | 0.75 |

| E2V | 3 | 17 | 0.79 | 2.87 | 1 | 2.84 | 50 | 1.44 | 66.55 | 0.96 |

| EQ8 | 3.3 | 6 | 0.34 | 3.17 | 1 | 3.14 | 50 | 1.59 | 83.91 | 0.51 |

| EV6 | 3.3 | 8 | 0.37 | 3.17 | 1 | 3.14 | 50 | 1.59 | 82.97 | 0.54 |

| EK2 | 3.3 | 10 | 0.57 | 3.17 | 1 | 3.14 | 50 | 1.59 | 76.66 | 0.74 |

| EK7 | 3.3 | 12.7 | 0.57 | 3.17 | 1 | 3.14 | 50 | 1.59 | 76.66 | 0.74 |

| EY9 | 3.3 | 17 | 0.8 | 3.17 | 1 | 3.14 | 50 | 1.59 | 69.4 | 0.97 |

| E2W | 3.5 | 6 | 0.32 | 3.37 | 1 | 3.34 | 50 | 1.69 | 85.46 | 0.49 |

| E2X | 3.5 | 8 | 0.35 | 3.37 | 1 | 3.34 | 50 | 1.69 | 84.57 | 0.52 |

| E2R | 3.5 | 10 | 0.39 | 3.37 | 1 | 3.34 | 50 | 1.69 | 83.38 | 0.56 |

| E2Y | 3.5 | 12.7 | 0.29 | 3.37 | 1 | 3.34 | 50 | 1.69 | 86.35 | 0.46 |

| E3B | 3.5 | 17 | 0.79 | 3.37 | 1 | 3.34 | 50 | 1.69 | 71.51 | 0.96 |

| EQ9 | 3.8 | 6 | 0.33 | 3.67 | 1 | 3.63 | 50 | 1.84 | 86.38 | 0.5 |

| EV7 | 3.8 | 8 | 0.39 | 3.67 | 1 | 3.63 | 50 | 1.84 | 84.74 | 0.56 |

| EK3 | 3.8 | 10 | 0.35 | 3.67 | 1 | 3.63 | 50 | 1.84 | 85.83 | 0.52 |

| EK8 | 3.8 | 12.7 | 0.57 | 3.67 | 1 | 3.63 | 50 | 1.84 | 79.84 | 0.74 |

| E1A | 3.8 | 17 | 0.78 | 3.67 | 1 | 3.63 | 50 | 1.84 | 74.11 | 0.95 |

Using the table

1. Pick in the table the nominal gap NG(mm) the closest to the actual one in your application

2. Select the width W (mm) in order to fill the gap as much as possible

3. Verify that mG and MG values are within the tolerances of the nominal gap NG